The Art of Precision: Mazda Welders’ Masterpiece at the High-Quality Metal Products Skills Fair

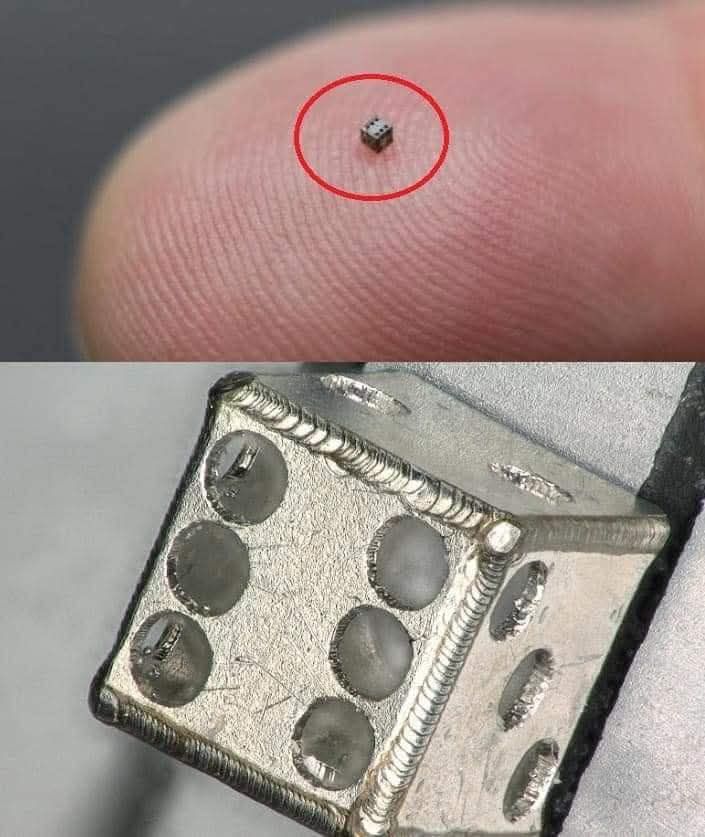

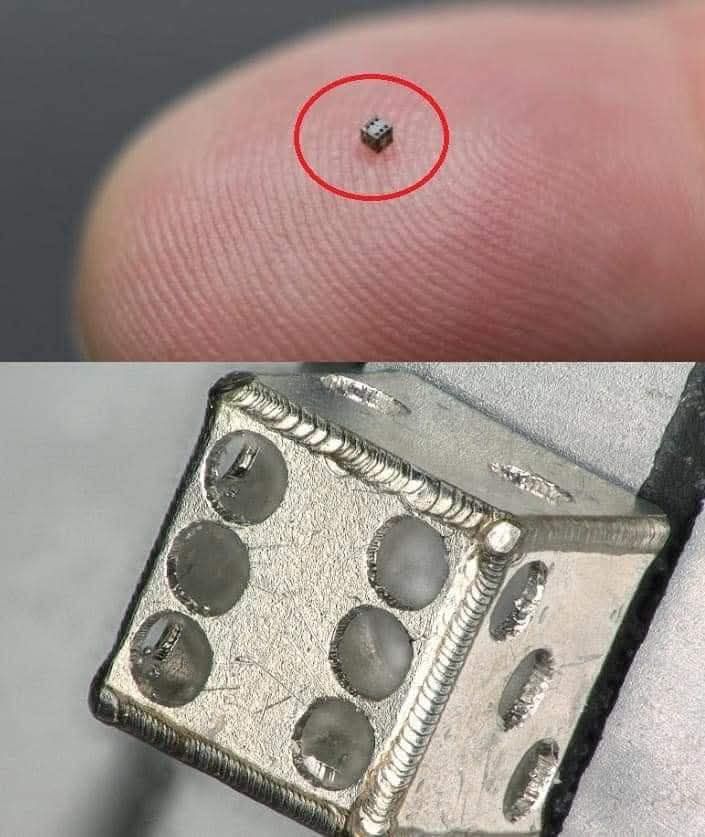

In the world of high-precision manufacturing, Japan has long been revered for its dedication to craftsmanship, particularly in the automotive industry. Mazda Motor Corporation, a brand synonymous with innovation and engineering excellence, once again demonstrated the remarkable skill of its welders at the “32nd High Quality Metal Products Skills Fair.” At this prestigious event, Mazda’s craftsmen showcased a piece that epitomizes their mastery: a meticulously crafted metal die, along with an even more astonishing creation—a miniature metal die measuring just one millimeter in size. This feat of engineering not only highlights the immense skill of Mazda’s welders but also underscores the company’s commitment to precision and excellence in metalwork.

The Tradition of Metalworking Excellence

Japan has a long-standing tradition of craftsmanship, known as “monozukuri,” which translates to “the art of making things.” This philosophy is deeply embedded in Mazda’s culture, where every engineer and craftsman is trained to strive for perfection in even the smallest details. The “High Quality Metal Products Skills Fair” is an annual event that celebrates this philosophy by bringing together some of the most talented metalworkers from different industries to demonstrate their capabilities. Mazda’s participation in this competition is not just a testament to their skills but also a reflection of their continuous pursuit of innovation.

The Craftsmanship Behind the Metal Dice

Mazda’s welders embarked on a challenging project for the fair: crafting a metal die using stainless steel plates. This was no ordinary dice; every face, every edge, and every corner had to be flawlessly welded to create a seamless and precise shape. The challenge was to ensure that each number was perfectly engraved and that the dice remained geometrically accurate. Given the nature of stainless steel, which requires specialized welding techniques to maintain its integrity and aesthetics, this was a test of both skill and patience.

However, Mazda’s welders took their craftsmanship a step further by fabricating an even smaller metal die, measuring just one millimeter in size. This tiny creation required extreme precision, as even the slightest miscalculation or uneven weld could have rendered the piece unusable. The ability to work on such a minute scale showcases a level of control and dexterity that few metalworkers in the world can achieve.

The Significance of Precision Welding in Automotive Manufacturing

While the creation of metal dice may seem like an artistic endeavor, it has significant implications for Mazda’s manufacturing processes. Precision welding is a fundamental aspect of automotive production, ensuring that every vehicle component is assembled with accuracy and durability. The same meticulous attention to detail used in crafting the dice is applied to Mazda’s vehicles, from the intricate welding of chassis components to the seamless integration of body panels.

Mazda’s dedication to craftsmanship extends beyond aesthetics; it directly impacts the performance, safety, and longevity of their cars. The techniques demonstrated in the skills fair reflect the company’s commitment to maintaining the highest standards in metalworking, which in turn contributes to the reliability of their vehicles on the road.

The Intersection of Art and Engineering

The ability to create such intricate metal pieces is not just a testament to technical expertise but also an art form in itself. Mazda’s welders blend science and craftsmanship to achieve results that are both functional and visually impressive. The miniature dice project serves as a reminder that true craftsmanship is not solely about large-scale production but also about mastering the fine details.

This pursuit of excellence is what sets Mazda apart in the automotive industry. While advanced machinery and automation play a crucial role in modern car manufacturing, it is the human touch—imbued with skill, precision, and passion—that elevates Mazda’s production quality. The ability to manually craft such tiny and complex pieces reinforces the idea that Mazda’s engineers are not just workers but true artisans of metal.

A Legacy of Innovation

Mazda’s participation in the “32nd High Quality Metal Products Skills Fair” is more than just a showcase of their welding expertise; it is a statement about their relentless pursuit of innovation. By pushing the boundaries of what is possible in metal fabrication, Mazda continues to inspire both within and beyond the automotive industry. Their ability to create something as small as a one-millimeter die with such precision speaks volumes about their meticulous approach to engineering and design.

The significance of this achievement extends beyond the competition itself. It serves as a source of inspiration for future generations of engineers, demonstrating that true craftsmanship requires patience, dedication, and a passion for excellence. In an era where automation and artificial intelligence are reshaping manufacturing, Mazda’s commitment to hands-on skill and artisanal precision ensures that the human element remains an indispensable part of the process.

Conclusion

The creation of the metal dice by Mazda’s welders is more than just an impressive technical feat; it is a symbol of the company’s unwavering dedication to precision, quality, and craftsmanship. Through this remarkable demonstration, Mazda reinforces its position as a leader in both automotive engineering and fine metalworking. As the industry continues to evolve, Mazda’s commitment to monozukuri—balancing tradition with innovation—ensures that their vehicles and manufacturing techniques remain at the forefront of excellence.

By celebrating the smallest details, Mazda proves that great engineering isn’t just about building cars; it’s about mastering the art of making things, down to the tiniest welds and finest finishes.